SWISS TYPE

ESPRIT SWISS TYPE MACHINING

Swiss Type Turning

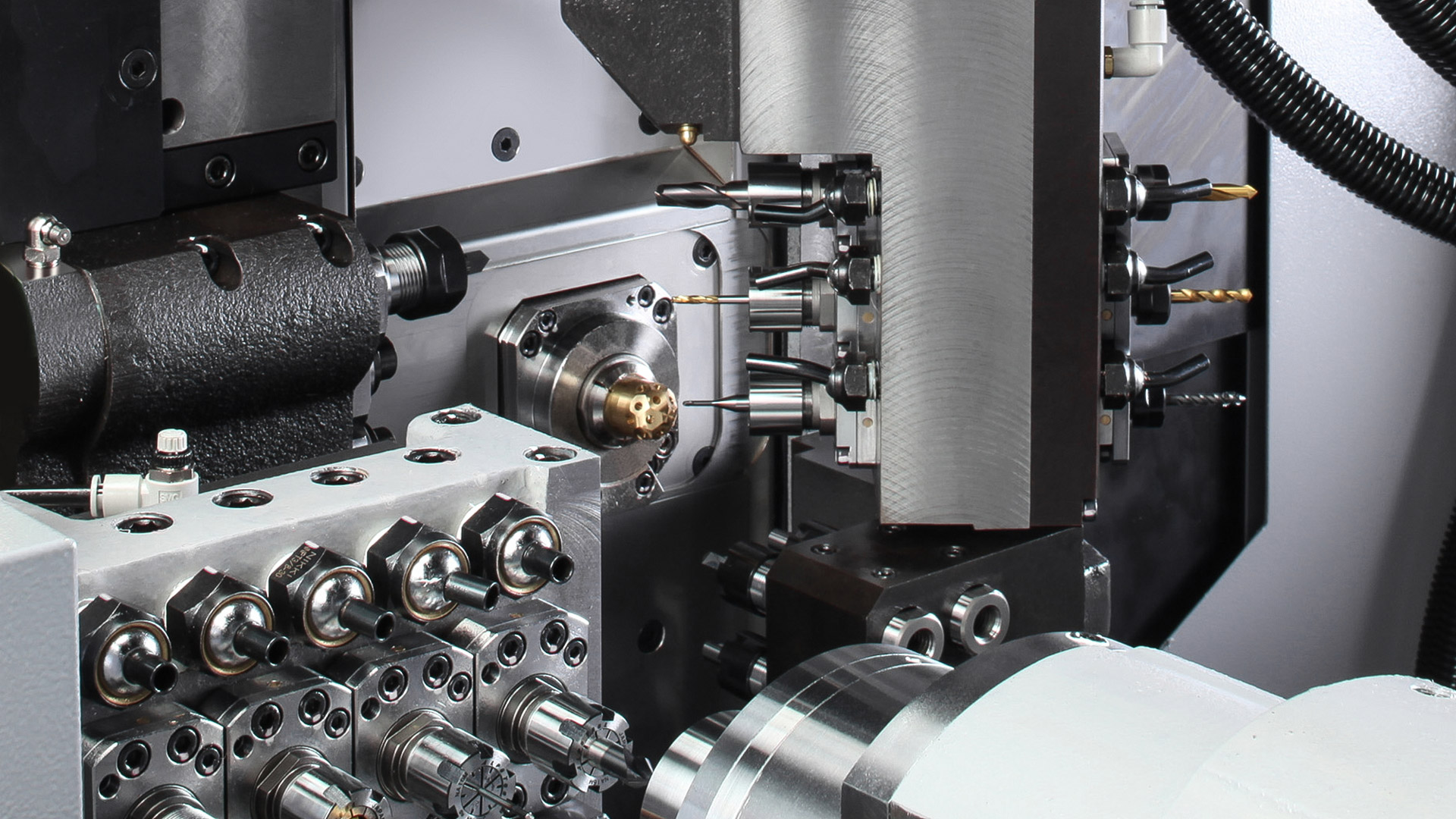

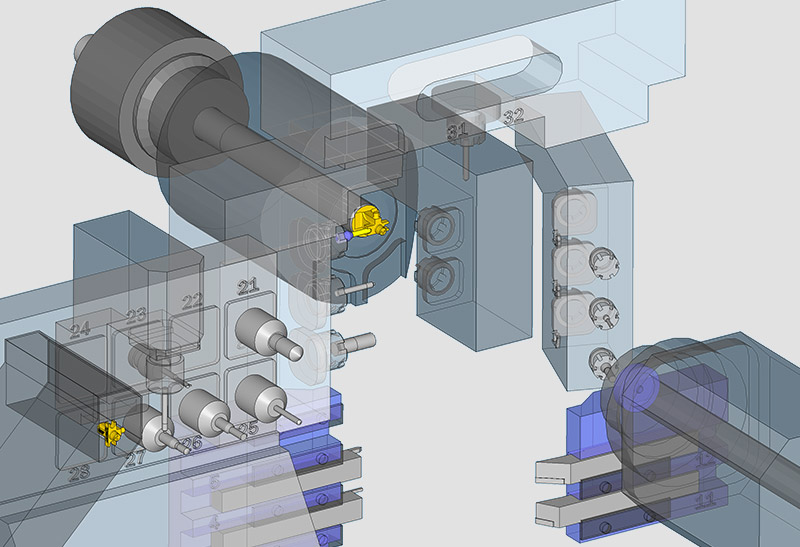

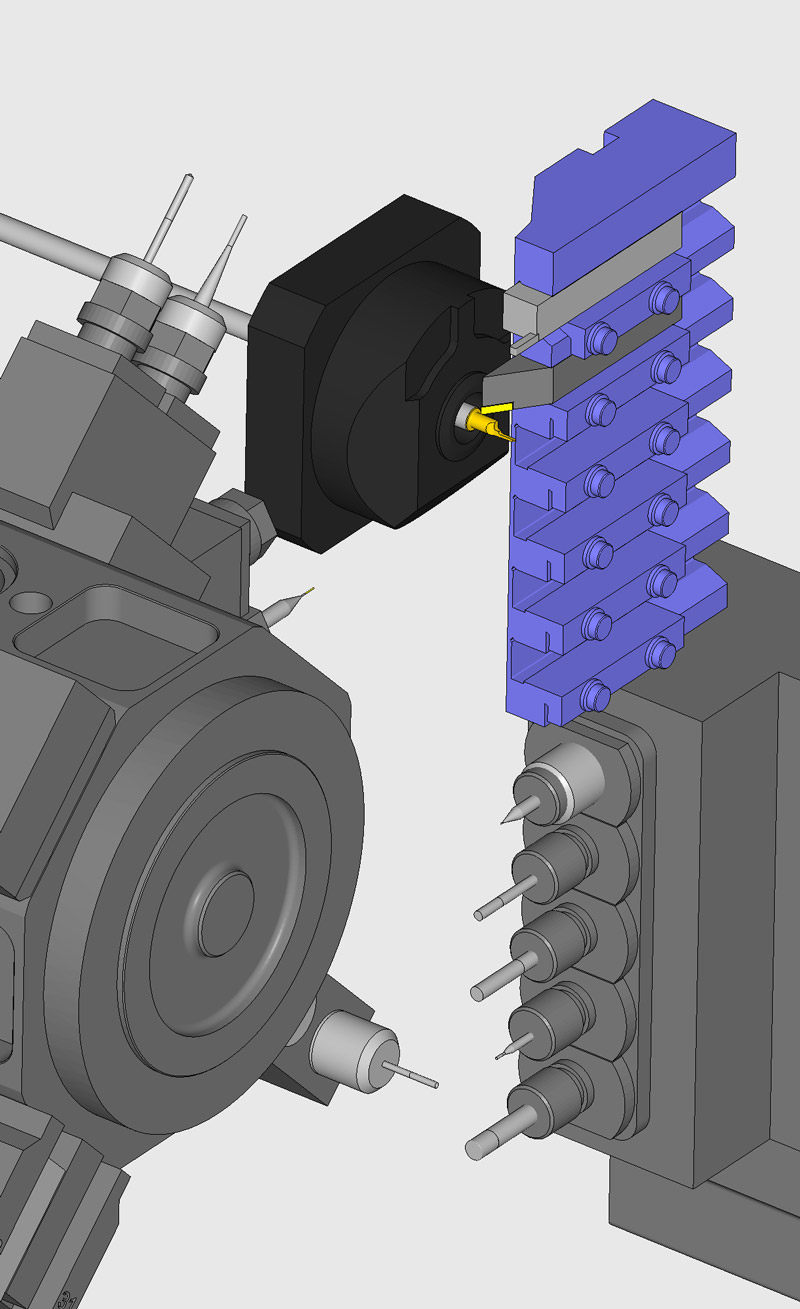

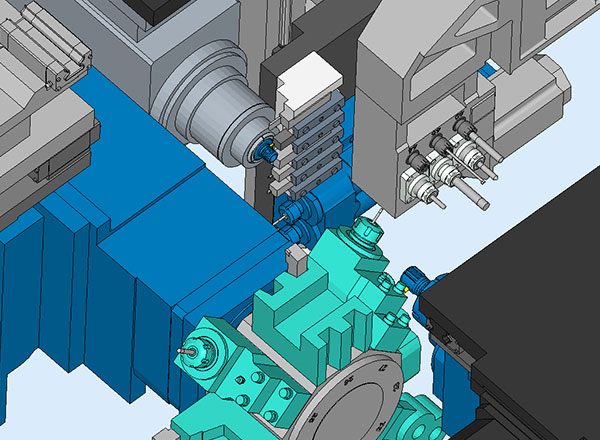

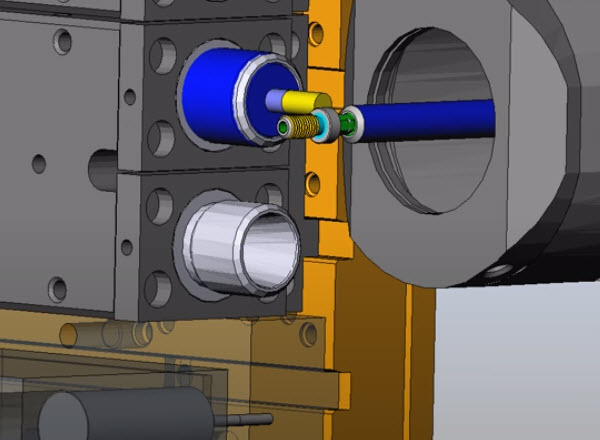

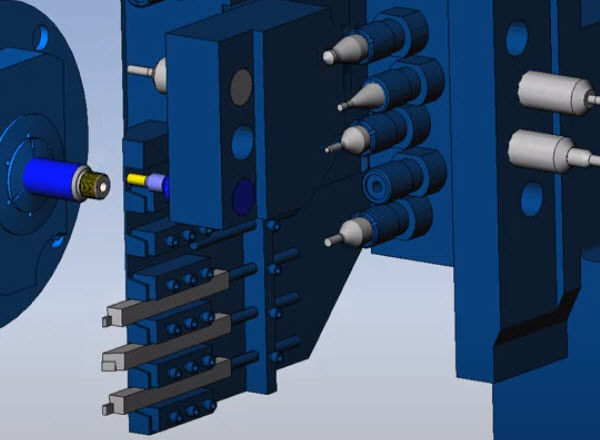

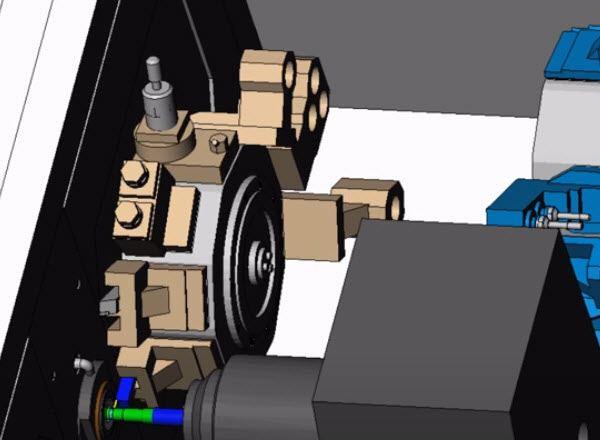

Swiss-type CNC turning centers are commonly used to machine complex parts, in small lots, with many cutting tools, in a single setup. To provide programming, optimization, and simulation specifically tuned for these machines, ESPRIT combines a comprehensive suite of milling, turning, and inspection cycles with support for Swiss-specific machine components — sliding headstocks, guide bushings, gang slides and posts for tooling, secondary spindles, and collinear axes. ESPRIT SwissTurn meets the unique challenges of Swiss-type turning with versatile support for turning and C-, Y-, and B-axis milling, all in the same G-code program.

- Versatile support for turning and C-, Y-, B-axis milling in the same program

Swiss Process Optimization

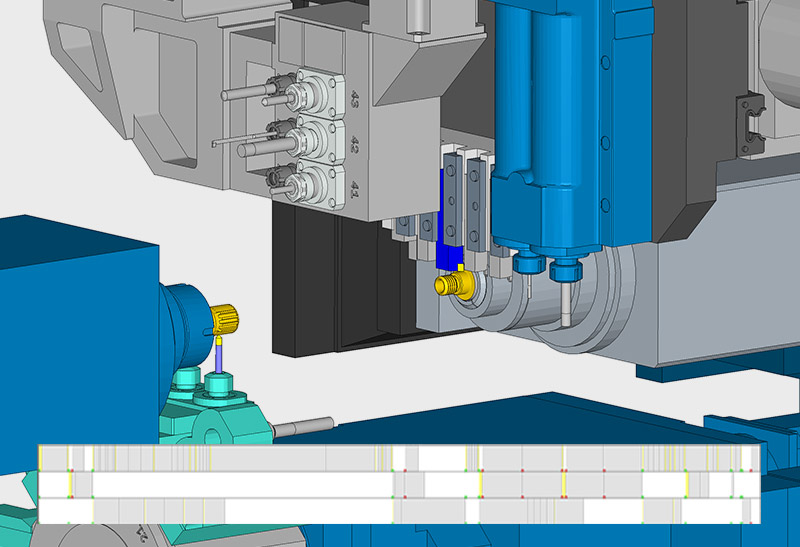

As a full-spectrum CAM system, ESPRIT delivers powerful programming, accurate simulation, and machine-optimized G-code for any class of CNC machine, limited only by the machine’s physical capabilities. ESPRIT employs a single user interface to program, optimize, and simulate machining tasks for milling, turning, wire EDM, and additive operations. To further reduce cycle times and extend tool life, ESPRIT offers patented high-speed machining strategies for Swiss turning centers and beyond.

- High-speed machining with ProfitMilling and ProfitTurning

Swiss Process Optimization

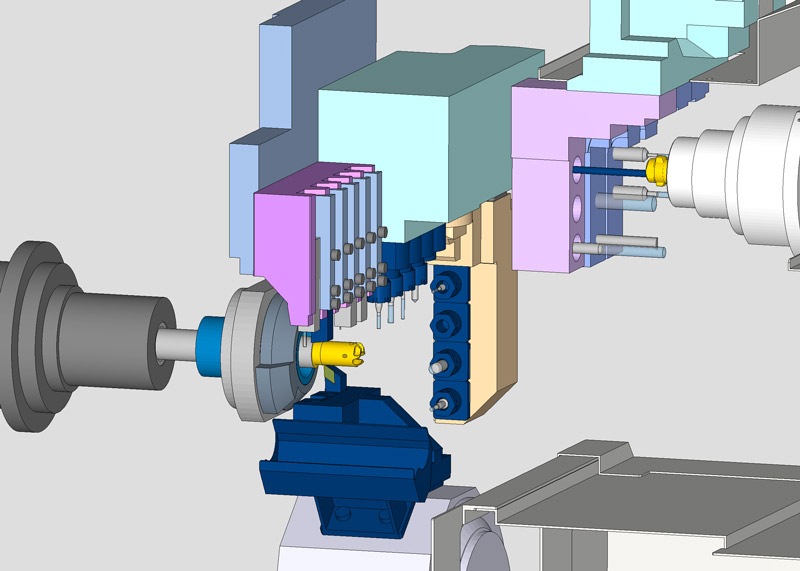

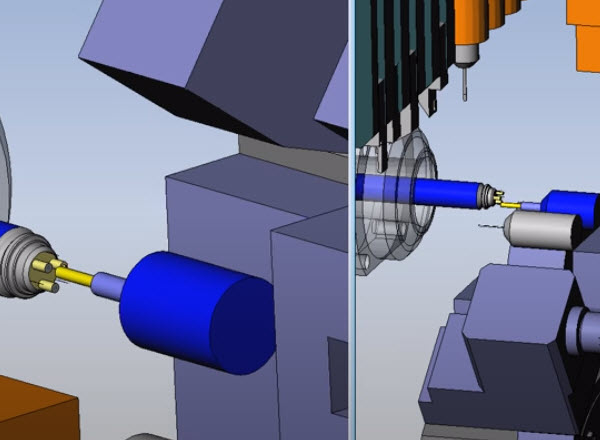

With SwissTurn, complete all machining on the part in one setup — even for parts that previously required multiple setups or even multiple machines. Process optimization strategies include segmentation of the program to take advantage of the guide bushing’s support for greater stability and more aggressive cuts, and specialized cutting cycles such as pinch turning and pinch milling that use multiple tools simultaneously within a single operation. Use machining patterns for synchronized and superimposed motion to optimize the cycle time for the overall process.

- Complete all machining on the part in one setup in the shortest possible cycle time

Swiss Verification

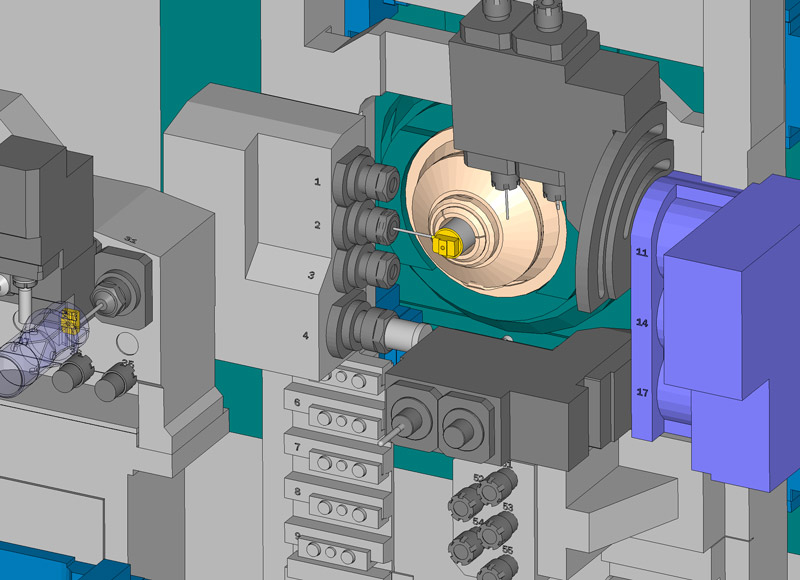

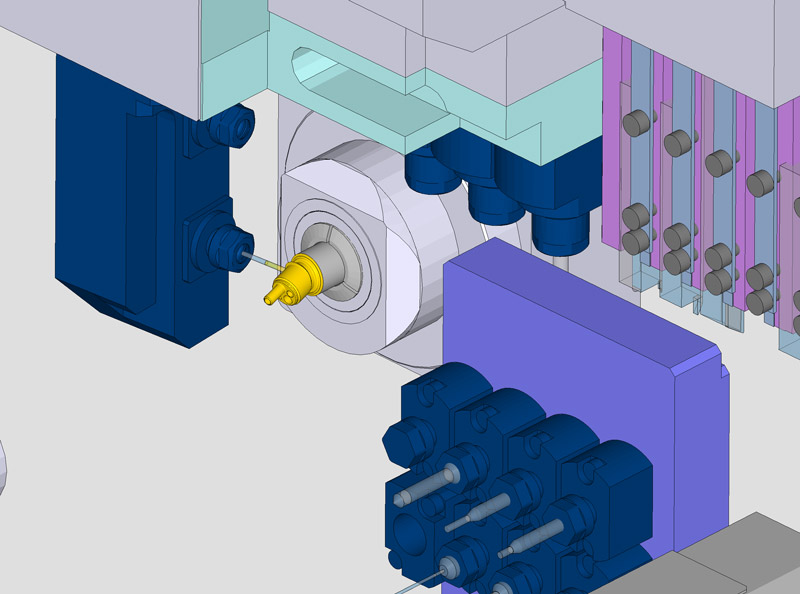

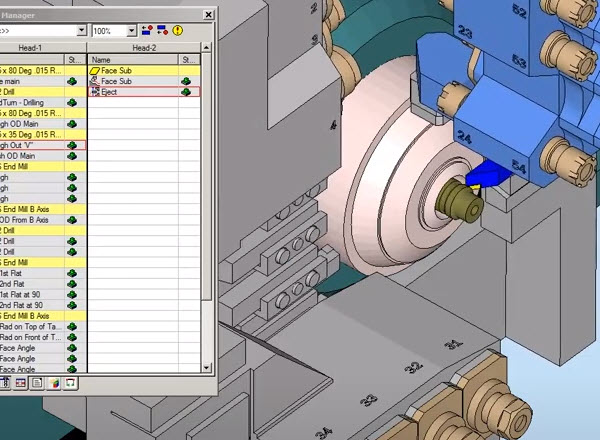

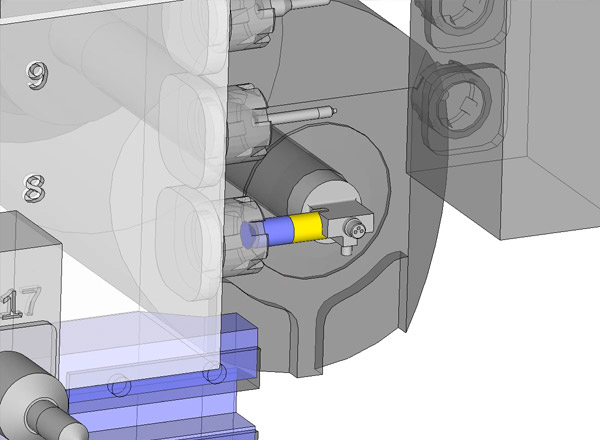

With ESPRIT, use the built-in machine simulation and verification to prove out programs beforehand and save valuable machine time. Based upon a digital twin of the Swiss machine, the simulation displays all the machining action in real time. This provides a highly accurate, animated view of the entire process, including the Swiss-specific cycles, motions, and components. Validate the program with collision detection between the tool, part, and all the components of the machine.

Swiss Time Study

ESPRIT delivers much more than just edit-free G-code for each channel, ready to run on the CNC, including the Swiss-specific functions. To help with costing and quoting, ESPRIT can provide time studies based on cycle times. Use the report generator to produce setup sheets designed to provide shop floor operators with an overview of the job, processes, and tooling. Tailor the format of this report to the preferences of each individual shop.

Swiss Partner Logos

ESPRIT offers individual solutions, built-in cooperation with each machine manufacturer, and tuned for each Swiss-type turning center. With ESPRIT, quickly move with confidence from design to finished part while minimizing programming and setup time, cycle times, and operator supervision.

- Delivering machine-optimized, edit-free G-code

Swiss-Type Specifications

The following packages of machining cycles are available from a common user interface to support any style of machining on any configuration of Swiss-type machine tool:

SolidMill

- All traditional milling 2.5-axis milling, ProfitMilling, plus optionally:

- C-axis index and rotary milling

- Y-axis, 3+1, index milling

- B-axis, 3+2, index milling

- 3rd rotary axis, 3+3, index milling

SolidTurn

- All traditional 2-axis turning cycles including:

- ProfitTurning

- Barfeeder, part catcher, and part handling cycles

- Collet and jaw chuck, modular and soft jaws

- Modular cutting tool assemblies with turret blocks and adaptive items

- Multiple spindles

FreeForm 3-axis, 4-axis, or 5-axis

-

Simultaneous multi-axis milling

Swiss-Type Machining

- Sliding headstock and collets

- Optional guide bushings

- Gang slides, front, back, and opposite tool posts

- Collinear axes

- Program segmentation

- Multiple programming channels with synchronization

- Machining modes enabling synchronized or superimposed motion

ESPRIT SwissTurn Machining Simulation

TSUGAMI Multi-Axis Swiss-Style Turning

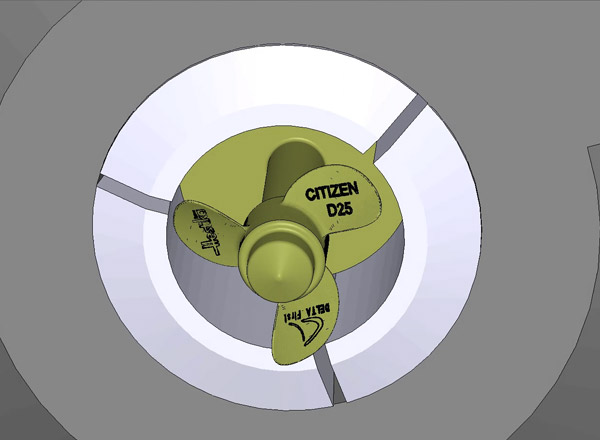

CITIZEN Multi-Axis Swiss-Style Turning

TORNOS Multi-Axis Swiss-Style Turning

DMG Sprint Multi-Axis Swiss-Style Turning

HANWHA Multi-Axis Swiss-Style Turning

STAR Swiss Style Fuel Injector

Citizen Propeller Swiss Type Machining

Star Swiss Style multi axis Simulation